Beijing Xianggu Technology Development Co., Ltd

Related websites

Subscribe us

Contact us

Document

Study on the film-forming property of MOF_5_PI mixed matrix

This paper, which was completed by a research scholar at Taiyuan Institute of Technology, discusses papers on the film formation of MOF-5/PI mixed matrix membranes and is published in the important journal

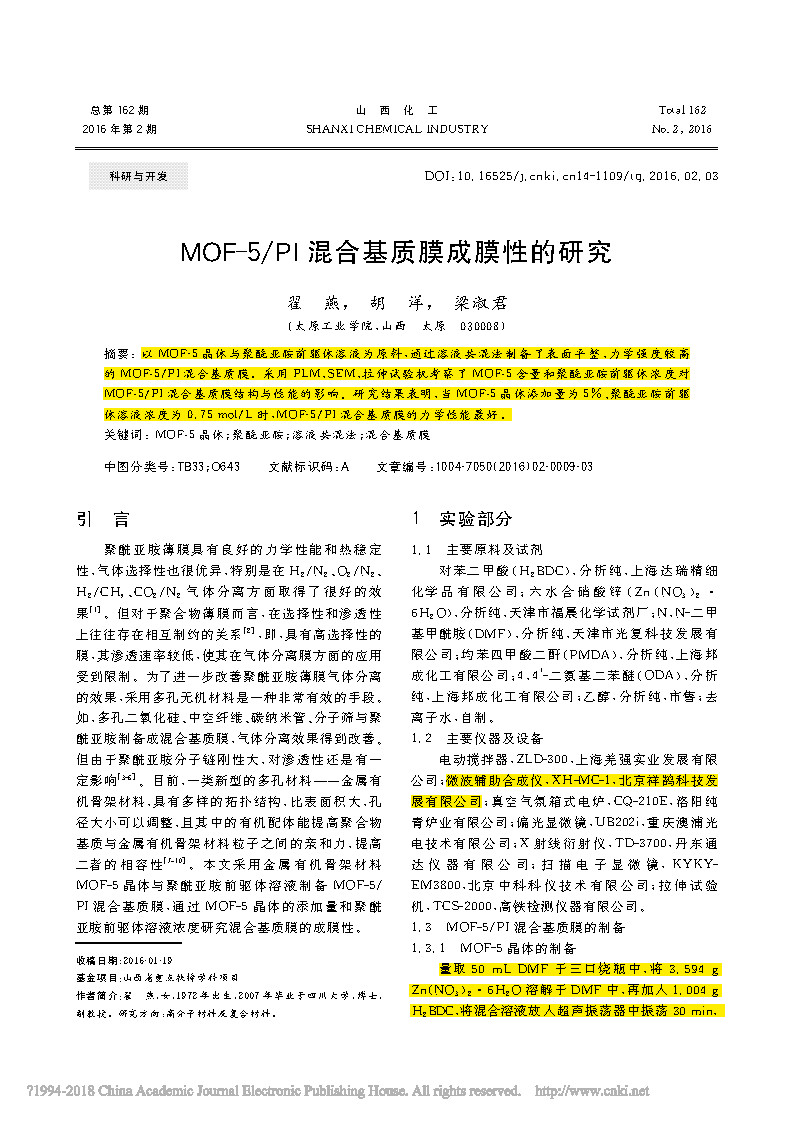

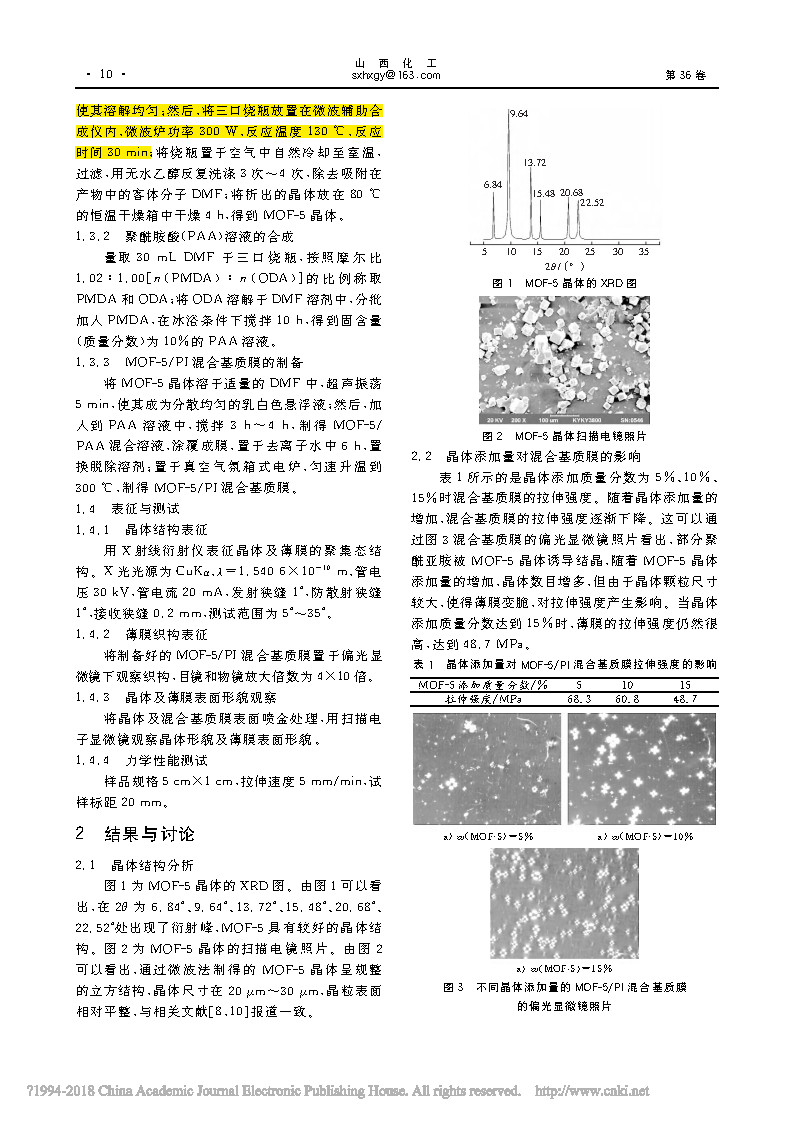

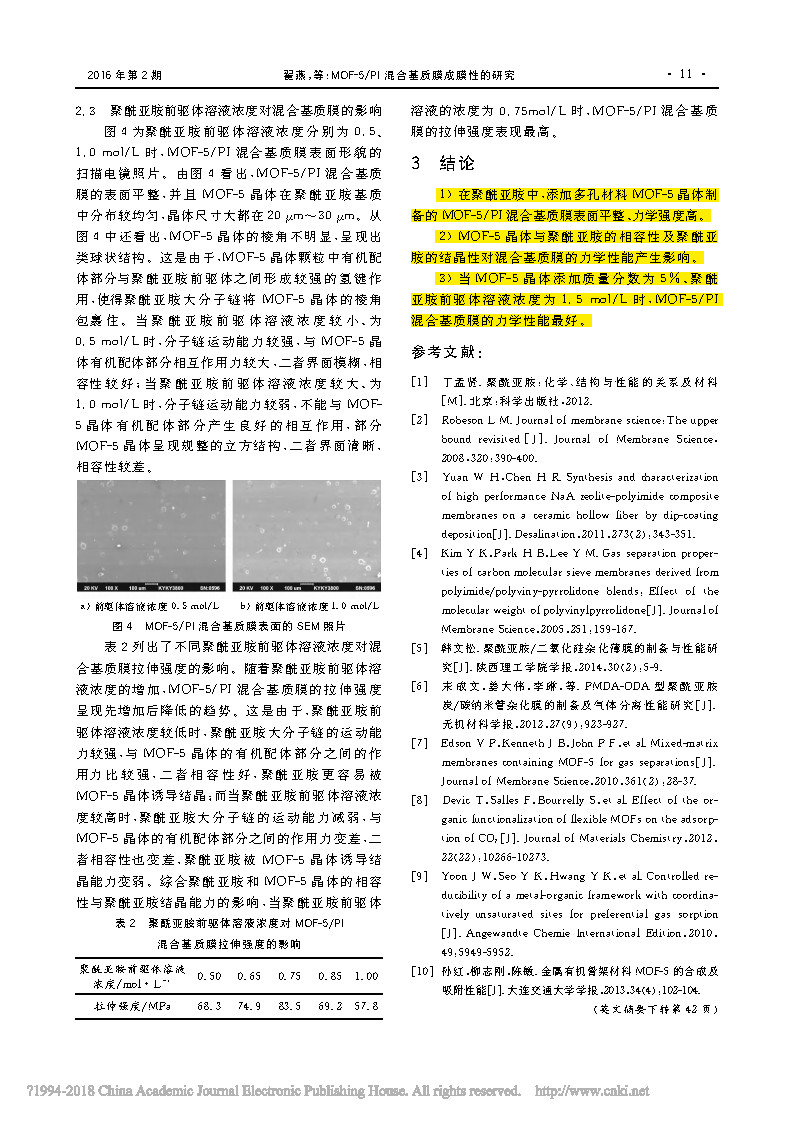

The MOF-5/PI mixed matrix membrane with smooth surface and high mechanical strength was prepared by solution blending method with MOF-5 crystal and polyimide precursor solution as raw materials. The effects of MOF-5 content and polyimide precursor concentration on the structure and properties of MOF-5/PI mixed matrix membrane were investigated by PLM, SEM and tensile tester. The results show that the mechanical properties of MOF-5/PI mixed matrix membranes are best when the addition amount of MOF-5 crystal is 5% and the concentration of polyimide precursor solution is 0.75mol/L.

Fig.1/3↑

Fig.2/3↑

Fig.3/3↑

1) In the polyimide, the MOF-5/PI mixed matrix film prepared by adding the porous material MOF-5 crystal has a smooth surface and high mechanical strength. 2) The compatibility of MOF-5 crystal with polyimide and the crystallinity of polyimide have an effect on the mechanical properties of the mixed matrix film. 3) When the mass fraction of MOF-5 crystal is 5% and the concentration of polyimide precursor solution is 1.5 mol/L, the mechanical properties of MOF-5/PI mixed matrix membrane are the best.

50 mL of DMF was weighed in a three-necked flask, and 3.594 g of Zn(NO3)2·6H2O was dissolved in DMF, and then 1.004 g of H2BDC was added, and the mixed solution was shaken in an ultrasonic oscillator for 30 minutes to dissolve it uniformly; The three-necked flask was placed in a microwave-assisted synthesizer, the power of the microwave oven was 300 W, the reaction temperature was 130 ° C, and the reaction time was 30 min. The flask was placed in the air and naturally cooled to room temperature, filtered, and washed repeatedly with anhydrous ethanol for 3 to 4 times. The guest molecule DMF adsorbed in the product was removed; the precipitated crystals were dried in a constant temperature drying oven at 80 ° C for 4 hours to obtain MOF-5 crystals.