Beijing Xianggu Technology Development Co., Ltd

Related websites

Subscribe us

Contact us

Document

8000 Study on Preparation of Fructose by Microwave Acidolytic Inulin

This research by Yancheng Jiekang Sucralose Manufacturing Co., Ltd., a paper on the study of fructose in the preparation of fructose in microwave acidolysis, was published in the important journal

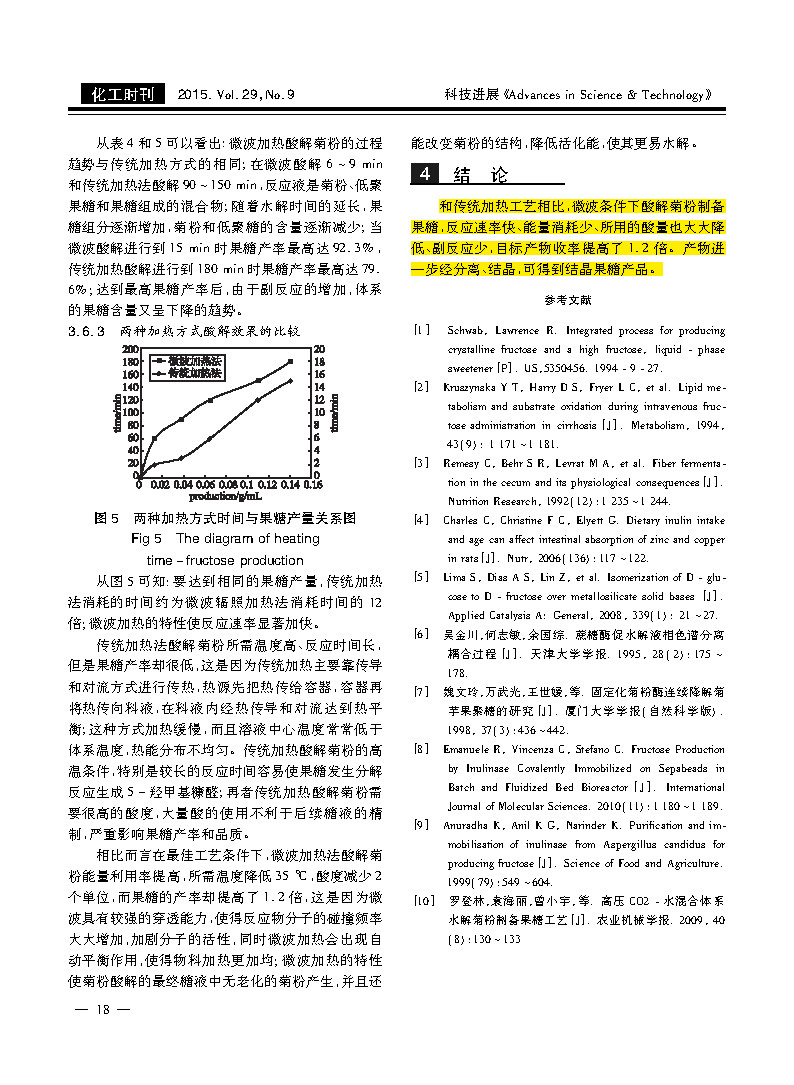

The preparation of fructose by acid hydrolysis of inulin under microwave condition was studied. The effects of inulin concentration, temperature, pH value and reaction time on the preparation of fructose by acid-soluble inulin under microwave condition were studied by single factor experiment. The optimum process conditions for inulin hydrolysis were determined: inulin concentration 15%, temperature 55 ° C, solution pH 5, microwave irradiation time 15 min, and fructose yield was 92.3% under this condition. Compared with the traditional heating process, the preparation of fructose by acidolysis inulin under microwave conditions has a fast reaction rate, low energy consumption, a large reduction in the amount of acid used, less side reactions, and an increase in the yield of the target product.

Fig.1/3↑

Fig.2/3↑

Fig.3/3↑

Compared with the traditional heating process, the preparation of fructose by acidolytic inulin under microwave conditions has a fast reaction rate, low energy consumption, a large reduction in the amount of acid used, and a small side reaction, and the target product yield is increased by 1.2 times. The product is further separated and crystallized to obtain a crystalline fructose product.

Add 60 mL of water to the PTFE bottle of the multi-purpose microwave chemical synthesizer, then add 5 mL of a certain concentration of dilute phosphoric acid and shake it. Then weigh a certain amount of inulin and add it to stir it completely. The air in the bottle was removed by N2, and the bottle cap was finally tightened and placed in a microwave reactor for acid hydrolysis to determine the fructose yield at different reaction times.